How To Repair And Paint Hard Plastic E30 Bumpers

why your bumpers appear off-shade from the residue of the automobile

Author: Andre Clemente, Founder of New Sometime Cars, LLC ©

Virtually the author

Last updated: July 16, 2022

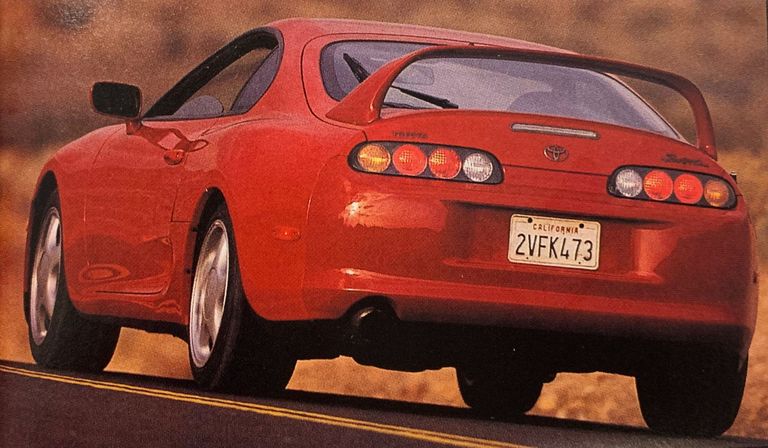

Photo Credit: David Dewhurst, Car and Driver 1993 Toyota Supra road test

One time you run across information technology … it'southward too tardily. There's no going back. You've been scarred for life.

We wish we could skip over it, or that it simply wouldn't bother us. Unfortunately, it'due south usually the biggest eyesore on modern cars (also orange peel, of course).

When rubber bumpers reached the end of their life during the late eighties/early nineties, manufacturers were assigned the task of paint matching a plastic bumper to a metal body. To make things difficult, they were experimenting with waterborne metallic paints for the first time, which requires an application and curing process much unlike than the solventborne paints they were used to. In add-on, bumper design began taking on a larger office in the overall design of the machine, and then the color match became absolutely crucial. You lot can imagine the headaches and long nights faced by the manufactory paint departments!

While it's yet noticeable on cars today, the cars produced from 1989-2005 had it the worst, and unfortunately, this era produced some of our favorite cars of all time.

TAP IMAGES TO REVEAL TEXT

In regards to the evolution of bumpers:

"The number of base-coat colors has increased and and so has the surface portion of outside plastic, whereas separate black trims between parts and machine body have almost disappeared," says Dr. Karl-Friedrich D¨ossel of DuPont (Axalta) Coatings (Automotive Paint and Coatings, 2nd Ed). "These factors make color matching betwixt form-integrated assembly part and car body a central upshot in testing optical properties of plastic coatings today."

Curiosity has us asking … what is the large deal? A mill pigment section can cost a manufacturer upward of $400 one thousand thousand, utilizing all the latest technology the earth has to offer – then how tin matching a plastic bumper to a metal trunk be that hard, even in the nineties?

NOC has decided to dig deep and find the respond. Analyzing the production process (both so and now), referencing factory training bulletins, assembly line videos, period and contemporary textbooks, also as theories and studies conducted by the pinnacle machine finish suppliers in the globe addressing this field of study. We want to know exactly what was going on behind those doors.

But before we break it down, lets first with the fact that bumpers are painted separately from the metal body. A auto is painted every bit a blank trounce with no bumper cover attached. Bumper covers are painted either by another supplier at a different location or in a carve up paint department in-business firm, known as "offline painting":

TAP IMAGES TO REVEAL TEXT

So why are they painted separately?

Well, there are quite a few reasons, but here are the master ones: Plastic bumpers can't handle the heat of the 300+ degree ovens used to thoroughly bake and cure a metal trunk. Secondly, the paint used on bumpers is different than the paint used on metal, as it needs to be flexible for "bumper duty". In addition, the metallic bodies are given a "charge" before they enter the paint booth, so that the oppositely charged pigment coming out of the fancy electromagnetic sprayers stick to the surface like a magnet. Manifestly a plastic bumper tin can't be charged like their metal counterparts, so they cannot exist painted together.

1. Scrap ORIENTATION NEVER MATCHES BETWEEN A PLASTIC BUMPER AND Metallic Trunk

Part of coming together customer demands and increased competition meant transitioning from the bland colour options of the 80'south into something new and enticing. While metallic paints have been around for decades, manufacturers were experimenting with this blazon of paint more than than ever at the plow of the ninety'south, producing special effect colors with big, coarse metallic flakes and high flake count.

The company Axalta (formerly DuPont), one of the top coating manufacturers in the world, states: "Call up of the aluminum flakes and pearls in the paint every bit tiny mirrors. When light shines onto a mirror's surface, it is reflected back in the exact contrary management. Similarly, when light shines onto the aluminum flakes in a vehicle'southward finish, the flakes are reflected back in a straight line to the opposite direction."

The event with metallic pigment jobs is that the flakes must have the aforementioned alignment between panels to look uniform. When aligned correctly, the sparkle on all panels will appear the aforementioned from all viewing angles. Still, if the flakes on 1 panel are aligned differently than the one next to information technology, the two panels will appear unlike to each other.

It is common to think that variations between paint batches (from being painted painted at a different location) is what causes this miracle on product cars. However any variations are extremely small (due to the intense quality control) and won't brand much of an impact in the overall appearance. Incorrect flake alignment plays a bigger office in the lack of uniformity betwixt panels:

TAP IMAGES TO REVEAL TEXT

2. PLASTIC REQUIRES A DIFFERENT Pigment SPRAYER

The higher momentum from the pneumatic sprayers forcefulness the flakes to "spread" and flow out differently, resulting in a sparkle that doesn't quite match that of the metallic panel adjacent to information technology.

3. PAINT CURES DIFFERENTLY ON PLASTIC, AND It CAUSES PROBLEMS

iv. THE Pigment USED ON BUMPERS HAS TO Exist More than FLEXIBLE

Bumpers are designed to absorb 5mph collisions, which requires the ability to flex upon impact. This means the paint on the surface has to exist flexible likewise.

Most manufacturers utilize a unique, "flexible" formulation of the body color paint to accost this for bumpers. In the 90's and early 2000's, for example, flex additives were used to make the paint permanently softer.

5. THE COLOR Match ISN'T VERIFIED Whatever Later on BUMPERS ARE MOUNTED

Part of the loftier tech paint inspection of the metal body is to compare and measure out flake orientation and DOI (prototype clarity) consistency between the body panels. Note that this is washed before the bumpers are installed. (run into below)

Since the bumper covers are painted elsewhere, they are not subjected to a comparative assay with the adjoining panel they bolt up to. They are individually inspected for imperfections once cured, and and so they are sent directly to the assembly line, where things like the interior and wheels are installed.

Sure, the employees give the car a once-over nether special lighting later on the bumper is installed, but the paint is not checked with any expensive equipment – just the human being centre and a manus wearing a special glove are used to spot defects. No further verification of color matching is washed between the bumper and neighboring panels. No spectrophotometer or DOI meter is used to verify fleck alignment or match the shade of the adjoining panels. One time it's on, that's information technology!

As ane of the leading textbooks on the field of study states: "Examination of color matching is non exclusively a matter of judgment by center but more and more a affair of physical measurements." (Automotive Paint and Coatings, 2nd Ed). Essentially, you demand actual measurements from defended equipment designed to measure gloss, color impression, DOI, etc from multiple angles. (Note: this doesn't apply to tactics utilized in the refinishing industry. The scientific measurements are needed to produce a repeatable effect on the product line in a timely manner).

Hither is a snapshot of what goes into inspecting the bare trounce afterward pigment (before the bumpers are installed):

TAP IMAGES TO REVEAL TEXT

Now, manufacturers could contend that bumper covers don't require such thorough inspection after installation … the pigment application process has avant-garde then much, and the quality control is so high, that today's bumper covers friction match pretty closely "out of the box". Plus, some car makers will occasionally carry tests on a sample run of cars (just near v% of cars are tested) with ultra modern equipment to ensure the pigment friction match meets their standard.

Just in the 1990's (and fifty-fifty early 2000's) this simply wasn't the example. The color friction match equipment bachelor at the time was but utilized by a few (if any) motorcar makers, as it was either besides large for the production line, besides complex, as well expensive, or information technology but didn't exist yet. As a result, cars were leaving the factory looking like this:

The infamous Toyota Supra with 7k original miles that sold on Bring A Trailer. Merely await at that rear bumper! When released in 1993, the Supra was offered with some of Toyota's virtually advanced paints at the time, including an all-new colour clear coat. Vibrant special-result and tri-coat colors were available, some with large flakes and high flake count that gave off quite a sparkle. A lot of "experimenting" was going on at Toyota'south pigment department, only not a lot of "perfecting" – the relatively new job of closely matching a painted bumper to a car trunk on the assembly line was easier said than washed (car makers were still transitioning from the unpainted bumpers of the fourscore'southward). Adding to the headaches was the fact that there was no ultra-advanced, multi-bending pigment evaluation equipment used by companies of today – the tech simply didn't exist yet. In the terminate, the just method that Toyota (and everyone else) had for confirming bumper color friction match was the proficient 'ol human eye (by visually comparison the bumper confronting some colour match exam squares on the occasional "sample" car). This inevitably produced mixed results depending on the color, viewing angle, and lighting. Only while this trouble was shared throughout the industry, some car companies produced better results despite facing the same hurdles.

And in Toyota's defense, not all of their cars were famous for such a paint mismatch between bumper and body – so what made this miracle such an eyesore on the Supra?

One could presume the fault lies in the paint quality control of the bumper supplier at the time, but that particular supplier provided Toyota with bumpers to more just the Supra. Plus, other Toyota and Lexus models wore exactly the aforementioned paint colors (given different names, merely same paint code) and information technology wasn't nearly as obvious equally the Supra. So … what gives?

Blame the pattern of the rear end.

Simply THE BUMPER ON MY Automobile MATCHES PERFECTLY?!

And when it comes to metallic paints, it doesn't matter how "easy" or "difficult" the color is to friction match – if the flake orientation is off, you'll notice a lack of uniformity. According to Axalta,"Flop variations occur with pearl and metallic colors. Solid colors do not showroom flop". This does not imply that solid colors are exempt from paint mismatch, all the same. Just await at Supra on this folio – Renaissance Red is a non-metallic paint.

SUMMARY

Manufacturers aren't stupid. They acknowledge the difference in appearance between the bumpers and metallic torso, but ensuring an absolutely perfect match isn't viable in the product procedure without high expense.

"In serial production, it can be seen that the high demands in color matching of associates parts upward to now, succeed only at high expenses. Information technology seems that a further increase of the plastic with body-colored surface depends largely on the cost construction," says Dr. Karl-Friedrich D¨ossel.

Retrieve, the manufacturer is capable of finding a solution for just nearly anything, but because they build cars for a profit, they have to cut expenses where they can. Equally long as the color friction match between trunk and bumper embrace run into their minimum acceptable standards, they are happy with it.

Other articles yous may savour:

Author:

Andre Clemente, Founder of New Onetime Cars, LLC ©

Article last updated: July 16, 2022

Virtually the Author: Andre Clemente, a member of the Society of Automotive Historians (SAH), has spent over 12 years in the business of buying and selling cars – half of those years were defended to the archetype car/sports car business. As an automotive pigment fanatic, Andre has been hyper-focused on learning paint correction and inspecting automotive paintwork, working alongside veteran dealers, brokers, and a licensed Concours approximate in the procedure. Years of existent-world practice and application gave him the feel to identify inaccuracies and myths that are widely accepted when authenticating a vehicle's paint job. Rather than keep his noesis as a trade clandestine, he has decided to share the research and insider details he's learned to aid educate the collector car customs on everything related to paint inspection and preservation of "new" onetime cars.

Additional Sources:

The top coating manufacturers in the globe (BASF, Axalta, PPG, as well equally paint evaluation tool suppliers similar BYK) spend hundreds of thousands of dollars conducting tests, instance studies, and other forms of enquiry. This cloth is supplied to car makers to aid educate them on why they need to invest in their tools and equipment in guild to relieve money in the paint shop and produce a amend looking product. Much of this cloth is available online in the form of textbooks, brochures, in-depth papers, and more. While highly technical, NOC's featherbrained obsession for knowledge on this topic means we dissect virtually annihilation we can become our hands on, choice out the interesting stuff, and highlight it in our articles. Below y'all'll observe some of the material used for this article:

Uniform Color and Appearance of Exterior Automotive Finishes: BYK Gardner

A Journeying Into the History of Gloss Measurement – BYK

Intro to Metal Colour by BYK Gardner: Influence of flake Orientation

on total colour impression

Color Theory by Axalta

Colour Matching for Metallic Coatings by Jayant Silva and Kristin J. Dana – Rutgers University

BYK Additives and Instruments: Solutions for Coatings and Plastics

Streitberger, Hans-Joachim, and Dössel, Karl-Friedrich. Automotive Pigment and Coatings, 2nd Edition – Chp 9: Coatings for Plastic Parts. WILEY-VCH Verlag GmBH & Co, 2008.

BYK Gardner: Solutions for Coatings and Plastics 2010/2011

Collision Repair Information for the Toyota Dealer: Waterborne Paint Guide and Repair

Sherwin-Williams Training Bulletins: Flex Additives

Volkswagen VW Golf 7 Car Factory Production Plant [GOMMEBLOG]

BYK Gardner – In the History of Gloss Measurement

BYK Gardner Advent Measurement Equipment

…and many more! NOC takes incredible pride in posting only the most accurate information with the help of credible sources. At present, because some links are no longer active, not all sources are posted here. These links take been removed from the source'southward website for unknown reasons. Notwithstanding, NOC downloads and retains all sources used to stand up by every argument in this commodity. This is done for all articles on our website, and NOC is happy to share this information with the public. Your trust is our number one priority.

– COMMENTS –

How To Repair And Paint Hard Plastic E30 Bumpers,

Source: https://newoldcars.com/why-are-bumpers-a-different-shade-from-the-rest-of-the-car/

Posted by: wattsgase1970.blogspot.com

0 Response to "How To Repair And Paint Hard Plastic E30 Bumpers"

Post a Comment